Please choose an option:

OVERVIEW

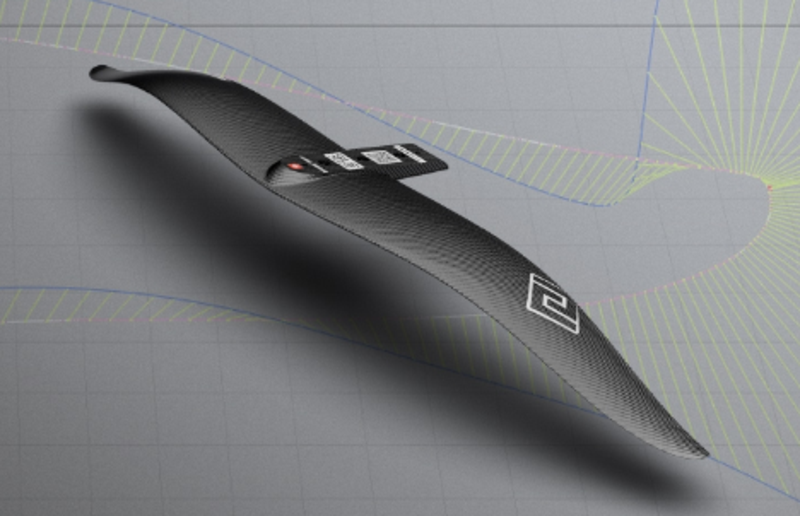

Our front wings have the best thickness-to-strength ratio on the market resulting in ultra-stiff wings with controlled flex patterns. Our production process has been optimised to have the lowest tolerances in the windsurfing industry.

-

“DNA-M” for “Medium” stiffness. More power for heavy riders and lighter winds. Affordable pricing.

-

“DNA-H” for stiffness level “Hard”. Maximum control in high winds, high speed runs and jibes.

- "DNA-X" for ultimate stiffness on the thinnest profiles technically possible

| SIZE | SPAN | RATIO | RANGE OF USE | CONSTRUCTION |

| 375 | 620 mm | 10.25 | speed, slalom, longdistance | hard / medium |

| 400 | 620 mm | 09.61 | high-wind slalom | xtra |

| 450 | 680 mm | 10.28 | slalom, wing speed | hard / medium |

| 550 | 750 mm | 10.23 | slalom, wing racing | hard / medium |

| 650 | 810 mm | 10.09 | low-wind slalom, wing racing | hard / medium |

| 750 | 850 mm | 09.63 | course racing, winging, freerace | hard / medium |

| 900 | 900 mm | 09.00 | course racing, winging, freerace | hard / medium |

CONSTRUCTION

To protect the advantage of having the stiffest parts we won’t name any construction secrets for the AEON frontwings.

As the only brand in the history of windsurfing being able to successfully produce hollow boards in more than 20 sizes (AirInside) our know-how in composite construction technology is literally miles ahead of competitor brands. With our own production setup of “Fullcore” boards (EPS Core) we’ve set the industry’s bench mark for weight and tolerance quality of EPS production boards. With our AEON foil constructions we are leading the industry again by offering the thinnest and most high-aspect designs with the stiffest flex vs twist ratio.

All foil parts are fitted with TX30 torx screws.

All frontwings are using m8 TX30 screws to secure the frontwings to the fuselage as we've tested that m6 screws - as used by many brands - are not reliable enough.

SANDING AND WARRANTY:

All AEON carbon parts have a "clear cote finish" to look optically appealing and perfect. This coating is sealing the carbon layers. Please note that sanding off this factory coating - partially or completely - will end the product warranty and any sanding will be fully at your own risk. Sanded AEON parts will change their look from glossy to matt finish. Always get some advise and guidance from experienced racers before sanding your foil parts. There is no general need to extensively sand the AEON carbon parts as we're using a very advanced production process. Only do so if you're 100% sure about what you're doing and why you're doing it.

CONCEPT

DESIGN GOALS

Our target was to create high-performance foils with full compatibility for all foiling sports and disciplines.

We wanted this foil system to be commercially available at different price levels from the “whatever-it-takes world cup level” to the demanding needs of more price sensitive customers. The AEON has been designed for maximum control – easing the fight of mastering 3-dimensional flight for both the skilled world cup rider fighting in the pack and the indermediate rider. Having one connection system for wind-, wing-, prone- and kite-foiling is a massive economic advantage for multi sport users and allows every rider to find his perfect personal setup easily. At the same time the multi-sport option opens a much bigger market to resell AEON foil parts. The AEON will be vailable in our retail network as a complete high-performance foil system that can fulfil any waterman's wishes and needs. One system can do it all!

MAN VS. MACHINE

The massive success of the AEON-Foil in both Windsurfing AND Wing-Foiling is the result of our PATRIK R&D crew’s precise and hard work. Our products are being developed in a unique hybrid process where the human brain (knowledge) and hands (feeling) are clearly leading the computer aided design – not the other way around. Like this we’re able to design perfect products that no “A.I.” (artificial intelligence) could ever create.

Fun-Fact: CFD (computational fluid dynamic) programs are created by humans, fed with data based on past practical tests, but will never be able to calculate completely new results outside their given data range. The PATRIK-Crew is practically developing and testing gear outside that software range and our results will be used later to feed and update currently available CFD programs.

SINGLE PARTS VS. SETS

After our R&D Team had found peak performance in individual outlines and shapes they had individual wishes for flex and twist resulting in different “magic” combinations of AEON parts. Offering all parts separately gives the top riders the freedom to find their magic setup while the indermediate riders can choose the best combo for their budget.

SETUPS

"Michele Becker" PWA Slalom Setups

95 Dim-S Mast, 400 DNA-H Frontwings, 100 V2 Titaninum Fuselage, 150 Backwing in rear position +1° shim

95 Dim-S Mast, 450 DNA-H Frontwings, 100 V2 Titaninum Fuselage, 160 Backwing in rear position +1° shim

95 Dim-S Mast, 550 DNA-H Frontwings, 100 V1 Titaninum Fuselage, 160 Backwing in middle position +1° shim

"Alex Cousin" 6.0 PWA Slalom Setup

95 Dim-S Mast, 400 DNA-X Frontwings, 100 V3 Titaninum Fuselage, 150 Backwing in rear position +1.5° shim

"Elia Colombo" 9.0 Course Racing Setup

100 Dim-L Mast, 900 DNA-H Frontwing, 110 V1 Aluminum Fuselage, 195 Backwing in rear position +1° shim

"Nico Warembourg" 4.2 DEFI Setup

95 Dim-S Mast, 375 DNA-H Frontwings, 100 V1 Titanium Fuselage, 150 Backwing in rear position +1,75° shim

"Thomas Goyard" 4.5 DEFI Setup

95 Dim-S Mast, 375 DNA-H Frontwings, 100 V3 Titanium Fuselage, 150 Backwing in rear position +0,75° shim

"Patrik Diethelm" Freerace Setup

95 Dim-M Mast, 750 DNA-M Frontwing, 100 V1 Aluminum Fuselage, 195 Backwing in rear position +0,5° shim

Speed Foiling Setup

95 Dim-S Mast, 375 DNA-H Frontwing, 100 V3 Titaninum Fuselage, 160 Backwing in rear position +1,5° shim